Applications

The DIC systems from Correlated Solutions excel in every imaginable application.

Our digital image correlation (DIC) systems have been implemented successfully in a wide range of applications from automotive to biological, and size scales from microscopy to large structures. All DIC systems are sold as turnkey solutions, which are customized to your measurement needs. Our systems include all hardware, software, technical support, onsite installation, and equipment training. We are dedicated to providing our customers with quality technical support and free software upgrades for one year after the date you receive your system.

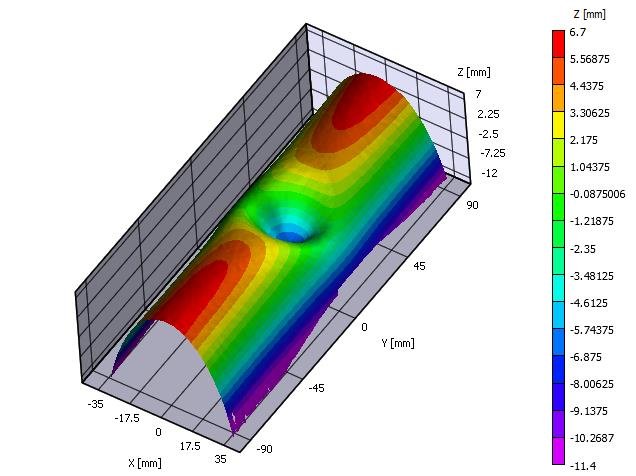

Analysis of Geometric Accuracy and Thickness Reduction in Multistage Incremental Sheet Forming using DIC

This paper describes a series of experiments in which truncated cone geometries were formed using two multistage methods and compared to the same geometry formed using the traditional single stage method. The geometric accuracy and thickness distributions, including 3D thickness distribution plots, of each are examined using digital image correlation (DIC).

DIC for Rail Neutral Temperature & Stress Measurements

The proposed method is based on measurements of nonuniform deformations of the rail under thermal loading, as observed in computer simulations and laboratory investigations. The implementation uses thermal imaging and three-dimensional stereo-digital image correlation technology to acquire full-field deformations.

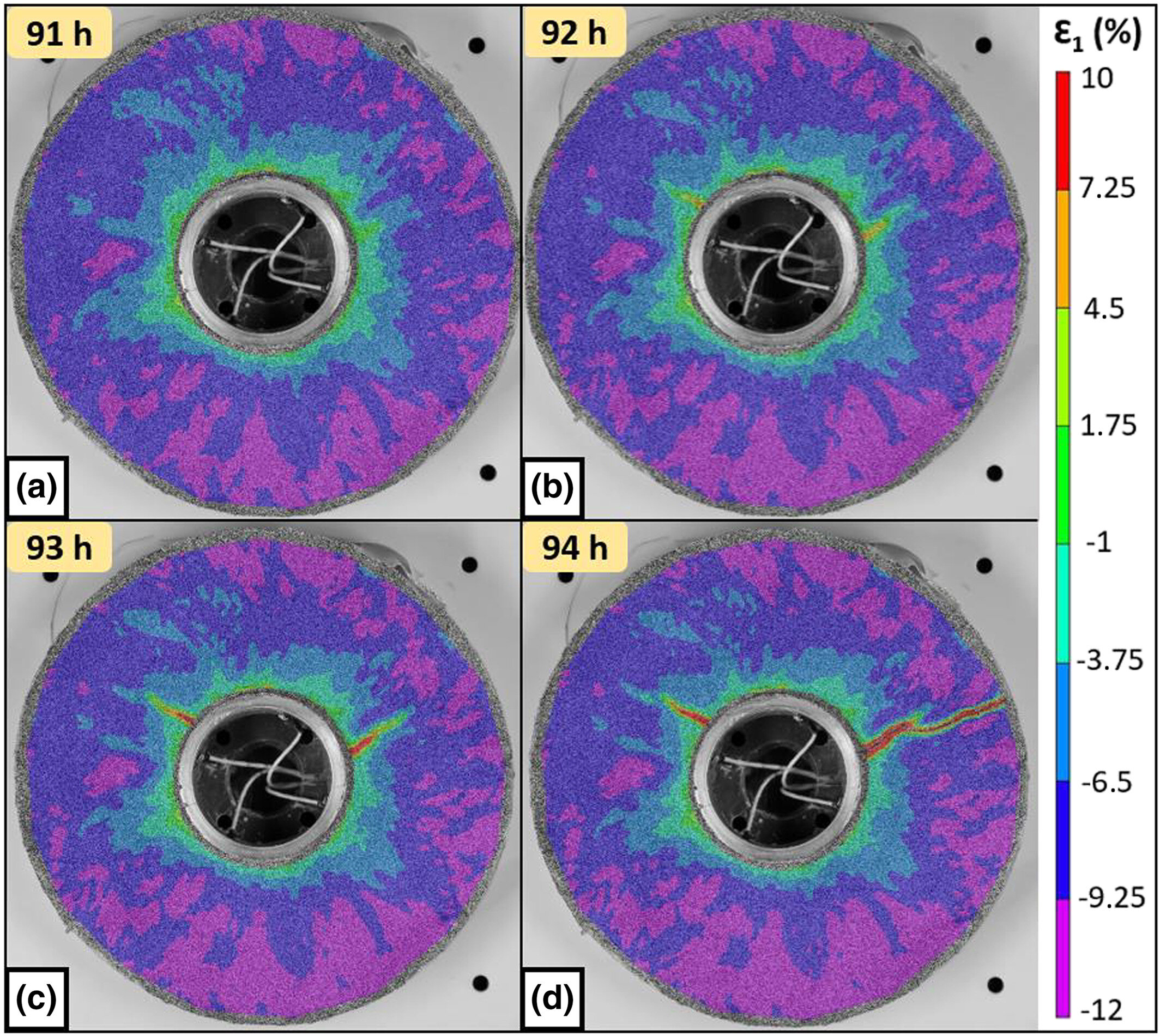

Analysis of Aneurysm Analogues using VIC-3D

To measure the inhomogeneous 3D-strain fields present during inflation-extension testing of physiologically submerged micro-aneurysms, a Stereo Digital Image Correlation (StereoDIC) microscopy system is developed that revolves 15° stereo-angle cameras around a centrally-mounted target. Calibration is performed using submerged dot patterns and system accuracy verified using strain and deformation analyses for rigid body motions of speckle-patterned, micro-aneurysmal surrogates. In terms of the Green-Lagrange strain tensor and the 3D displacement fields, the results are stable even after 120 minutes, with maxima in both strain bias and strain standard deviation less than 2E-03 for all components, and micron-level displacement standard deviation.

Measuring 3D Volume of Reinforced Rubber Matrix Composite

A reinforced rubber matrix composite is mounted between two grips, and a set of reference images are acquired from a CT scanner at know increments. Each ‘slice’ of data is then analyzed to compute a static volume measurement. After the specimen undergoes a tensile load, images are acquired again by the CT scanner at the same locations.

VIC-3D Stereo Microscope & Capacitor Chip Assembly

The VIC-3D Stereo Microscope System The VIC-3D stereomicroscope system enables local analysis within very small elements. One industry that benefits from this small field imaging is microelectronics.

Measuring 3D Volume of Rubber Torus

A rubber puck is mounted between two grips, and a set of reference images are acquired from a CT scanner at know increments. Each ‘slice’ of data is then analyzed to compute a static volume measurement. After the puck undergoes a compression load, images are acquired again by the CT scanner at the same locations. Digital Image Correlation algorithms are used to calculate the volumetric change or deformation at each individual voxel, which make up the 3D volume.

Thermomechanical Response Measurement on Composites Using Infrared Thermography and DIC

Understanding thermo-mechanical behavior of material can be a vital component when designing vehicles and structures that may become exposed to high temperatures. Virginia Tech’s Extreme Environments, Robotics, and Materials (ExtReMe) Laboratory focuses on the impact of extreme environments on materials. This includes research that is focused on understanding the thermo-mechanical behavior of materials both during and following fires. Experimental investigations are performed to understand the evolution of the material due to elevated temperature.

Behavior of Metals During High-Speed Dynamic Compression

Studying the behavior of metals during a high-speed dynamic compression event has always been challenging due to the complex test set up and fast data capture rates required. Currently, very little literature is available regarding deformation behavior at strain rates of 10 to 500s-1. Utilizing high-speed cameras, the VIC-3D HS system can be used to quantify the surface displacements and strains in three dimensions over the entire field with great precision. Digital image correlation (DIC) has gained widespread popularity over recent years in such high-speed applications due to its high accuracy, flexibility and ease of use.

Strains Within a 300µm Diameter Ball Solder in BGA

The VIC-3D Stereo Microscope System enables local analysis within very small elements. One industry that benefits from this small-field imaging is microelectronics. Small electronics, like ball grid arrays (BGA) seen here, are too far small for traditional DIC to provide enough resolution to obtain local strain distribution within the actual ball solder.