Fatigue Monitoring of a Dented Pipeline Specimen Using Infrared Thermography

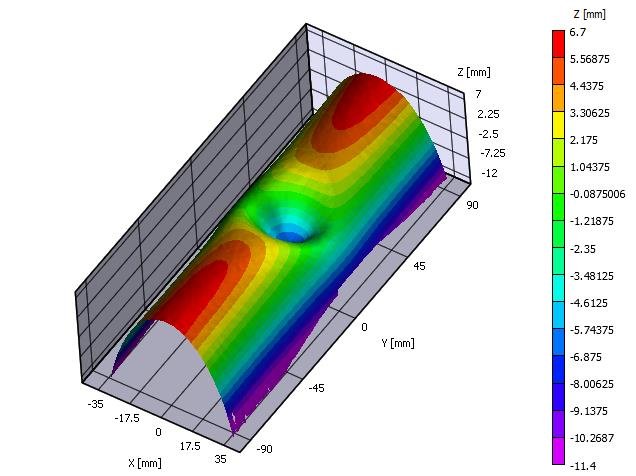

This work combines the fatigue properties rapid assessment approach using uniaxial test specimens proposed by Risitano and co-workers with the nondestructive testing inspection approach proposed by Sakagami and coworkers to monitor the onset of fatigue in a reduced scale pipeline test specimen that was previously dented and subsequently subjected to cyclic pressure loading. In addition to the use of the conventional infrared (IR) thermographic method, the present paper uses a self-reference lock-in IR thermography method based on Thermoelastic Stress Analysis (TSA) and its deviation from traditional applications due to the presence of fatigue damage and plastic strains. The paper concludes by showing that is possible to predict and monitor and detect fatigue initiation and damage using IR and TSA techniques applied to the thin wall pipe loaded under cyclic hydrostatic pressure.