Women in Engineering Using Digital Image Correlation

Throughout March and in honor of Women’s History Month, Correlated Solutions was proud to highlight Women in Engineering who use digital image correlation in their research. We reached out to these impressive engineers who are doing important work using digital image correlation in disparate arenas to ask them about their work and their experience as engineers.

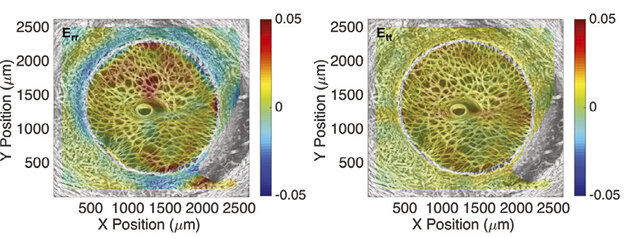

Dr. Kristin Myers

We begin the series with Dr. Kristin Myers and her groundbreaking work on the biomechanics of women’s health. Dr. Myers’s Soft Tissue Lab at Columbia University specializes in the female reproductive system. Her team utilizes experimental, theoretical, and computational mechanics to calculate and study the loading environment of pregnancy and postpartum recovery. Dr. Myers is a long time Correlated Solutions customer and uses DIC to validate her theoretical and computational modeling with experimental evidence.

Check out the following links for more information about her important work (including a feature in the Childbirth episode of the popular Netflix series called ‘Sex Explained’).

https://kristinmyerscolumbia.com/

https://www.technologyreview.com/…/the-science-of…/

https://www.netflix.com/title/81160763

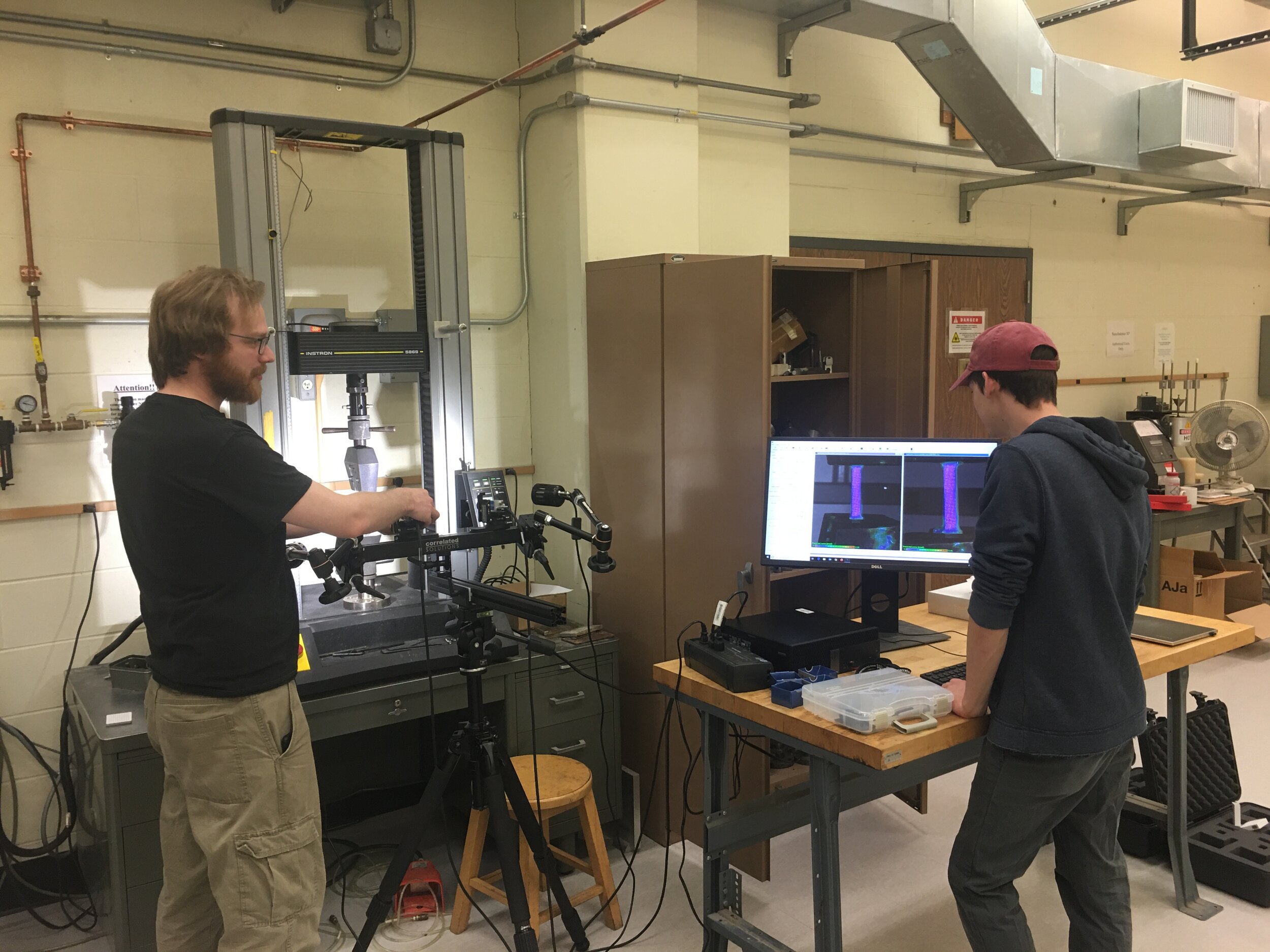

Dr. Allison Beese

Dr. Allison Beese at the Penn State Department of Materials Science and Engineering uses 2D & 3D DIC to quantify deformation fields in mechanical test experiments. She notes, “DIC is indispensable to our research. We use the DIC fields to calibrate and validate our computational models which in turn enable us to perform simulations to predict, and therefore prevent, fracture in load-bearing components.” Dr. Beese’s research focuses on uncovering links between the microstructure of metals and their mechanical behavior. This plays a role in enabling the safe adoption of additive manufacturing in structural components as well as the design of microstructures and materials for targeted applications.

Any advice for young women interested in an #engineering career? “Explore what interests you and use your imagination. Engineers work in a huge range of fields and do everything from fundamental research to very applied work. It is an exciting career path!”

Check out the following links for more information about Dr. Beese and her research:

https://research.matse.psu.edu/beese/

https://research.matse.psu.edu/beese/node/268/#Multiaxial

https://www.matse.psu.edu/directory/allison-m-beese

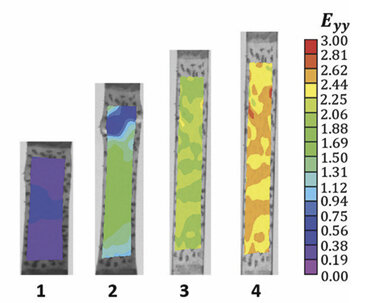

The Beese Lab at Penn State University

The next researcher we highlight as part of our #womeninengineering series is Dr. Lesley Frame at UCONN Materials Science and Engineering. The Frame Research Group focuses on alloy manufacturing and processing-property relationships. By determining these “transient” materials properties that are constantly changing during processing, Dr. Frame’s team builds realistic models that describe materials behavior during a manufacturing sequence. Digital image correlation allows her team to capture detailed deformation behavior during thermomechanical processing. In particular, they can quantify non-uniform deformation during testing and connect this to microstructures and other property measurements. This allows them to refine models by removing assumptions about uniform behavior.

Dr. Frame’s message to young women who aspire to engineering: “Don’t be afraid to try new things! There are several aspects to engineering (hands-on testing and measurement, characterizing materials, computer simulations and models, data analysis), and we need people who are excited by any or all of these. Also, don’t be afraid to fail. Often, you will learn more from doing something the wrong way, than getting it right the first time. Science and engineering is all about asking questions, and the individuals who will do well have in common a passion for figuring things out.”

Read more about Dr. Frame and her work here: https://frame.mse.uconn.edu/

Dr. Thao (Vicky) Nguyen

As we continue our series on #womeninengineering, today we focus on Dr. Thao (Vicky) Nguyen. In the Johns Hopkins University – Department of Mechanical Engineering, the Nguyen Lab studies the mechanical behavior of soft biological materials and polymers using an integrated experimental and modeling approach. Specifically, her team is interested in active polymers and tissues that can exhibit dramatic changes in microstructure, mechanical properties, and macroscopic shape in response to external stimuli. They deploy digital image correlation (DIC) and digital volume correlation (DVC) to study how the various features of the microstructure influence deformation mechanisms, mechanical properties, and function of the material. DIC is also used to investigate the underlying microstructural mechanism of the unique dissipative and active behavior of liquid crystal elastomers (LCE) to design architected materials for impact protection and soft robotics.

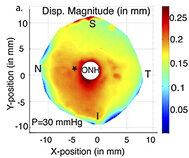

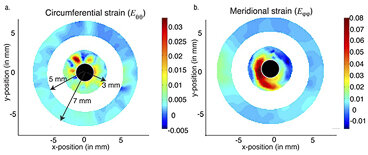

Looking ahead, the Nguyen Lab is focused on in vivo measurements of tissues. They are developing methods of using DVC to characterize in vivo mechanical behavior of the optic nerve head in glaucoma patients to understand how the tissues remodel (change) with disease and how mechanics can contribute to the development of the disease.

Dr. Nguyen’s advice for young women who aspire to a career in engineering: “Engineers are creative problem solvers and the world increasingly needs engineers to solve some of society’s most pressing problems. These include developing technologies to make renewable energy more affordable and reliable, combating water scarcity, and developing more advanced and affordable health care solutions. Engineers need a diverse set of knowledge and experiences to solve these challenging problems. Beyond math and science courses, I would encourage aspiring engineers to also pursue their interests in the arts and humanities, such as debating, history, writing, music, etc. This broader education will help them develop creative problem-solving skills, communication skills, and teamwork skills and become more effective leaders.”

https://engineering.jhu.edu/tnguy108/

We’re excited to highlight Dr. Sarah Bentil, the next in our series of #womeninengineering who use digital image correlation in their research. The Bentil Group at Iowa State University deals with soft tissue and biomaterial mechanics, and Dr. Bentil has a particular interest in understanding traumatic brain injury (TBI) mechanisms due to blast and/or blunt impact. The results from her team’s experiments will be used to improve clinical diagnostic tools and develop countermeasures (e.g. improve helmet design) to reduce or prevent brain injuries. Dr. Bentil’s lab uses three-dimensional digital image correlation (3D-DIC) analysis to quantify how the brain is deforming when exposed to a blast and/or blunt load. Finite element (FE) models, simulating the experiments, are then used to provide additional insight into the brain’s response. In the FE simulations, the 3D-DIC data is used for calibration and validation.

Connecting the deformation of the whole brain, measured using the digital image correlation method, with the structural changes of the brain cells (e.g. neurons and glial) is the next big thing. Making this connection will allow injury prediction to be possible. If you can predict the brain injury and its severity, then you have the power to design effective protective gear that can prevent the injury.

Dr. Bentil’s advice for young women aspiring to be engineers: “Find opportunities in your city or town, to participate in engineering-related activities and events. This way, you can meet female engineers at these events and ask them questions about how they became an engineer and what they do in their career. You can find these engineering-related activities and events by contacting the engineering departments at your local community college and/or university. At times, the science and math teachers at your local high schools or even your public library are aware of these events. So, get involved in engineering activities as soon as you can. Don’t forget to have fun with engineering along the way!”

Check out more of this fascinating, important research at the Bentil Group’s website: https://www.me.iastate.edu/sbentil/

and YouTube channel: https://www.youtube.com/watch?v=UuMvbgoHuZA

Dr. Sarah Bentil

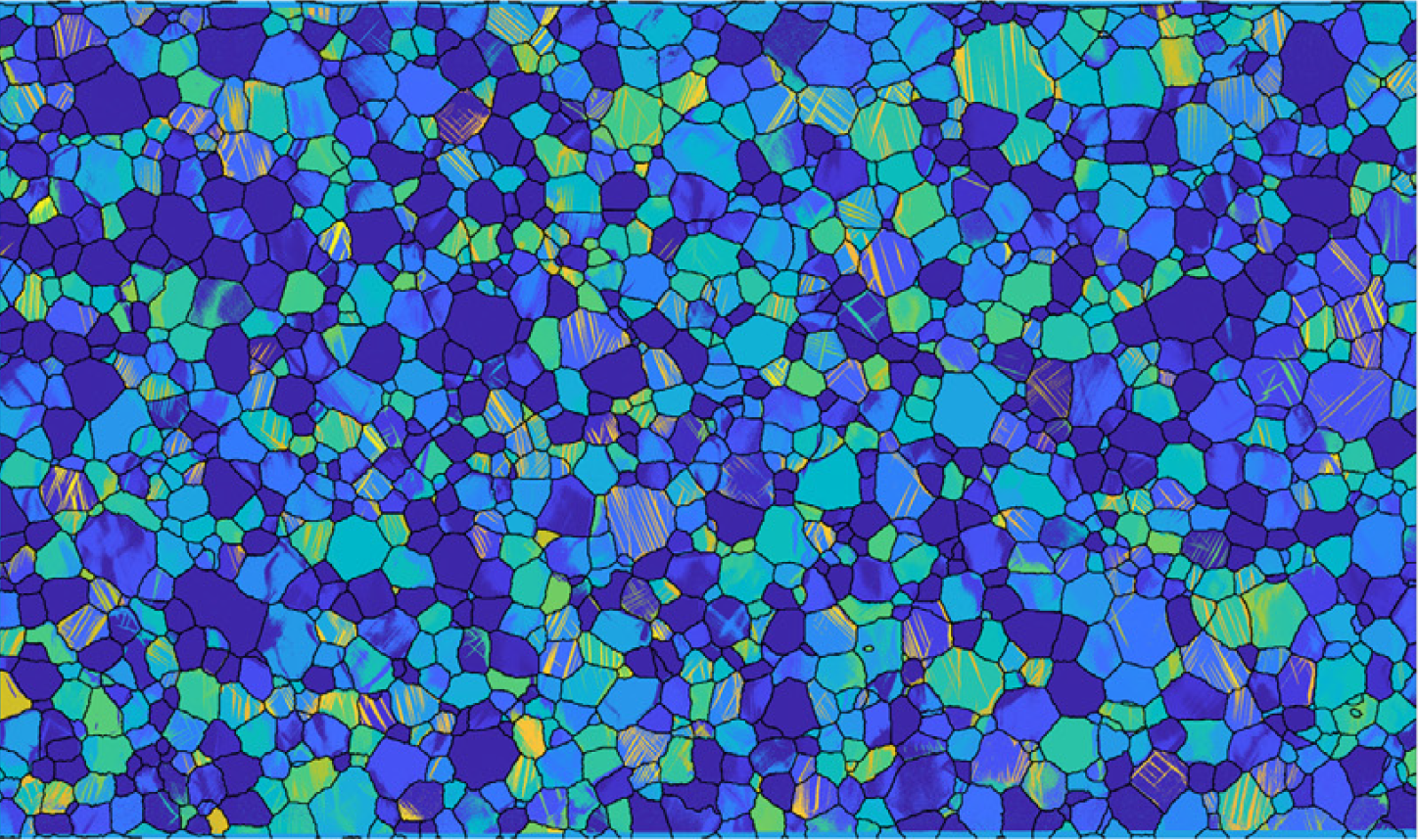

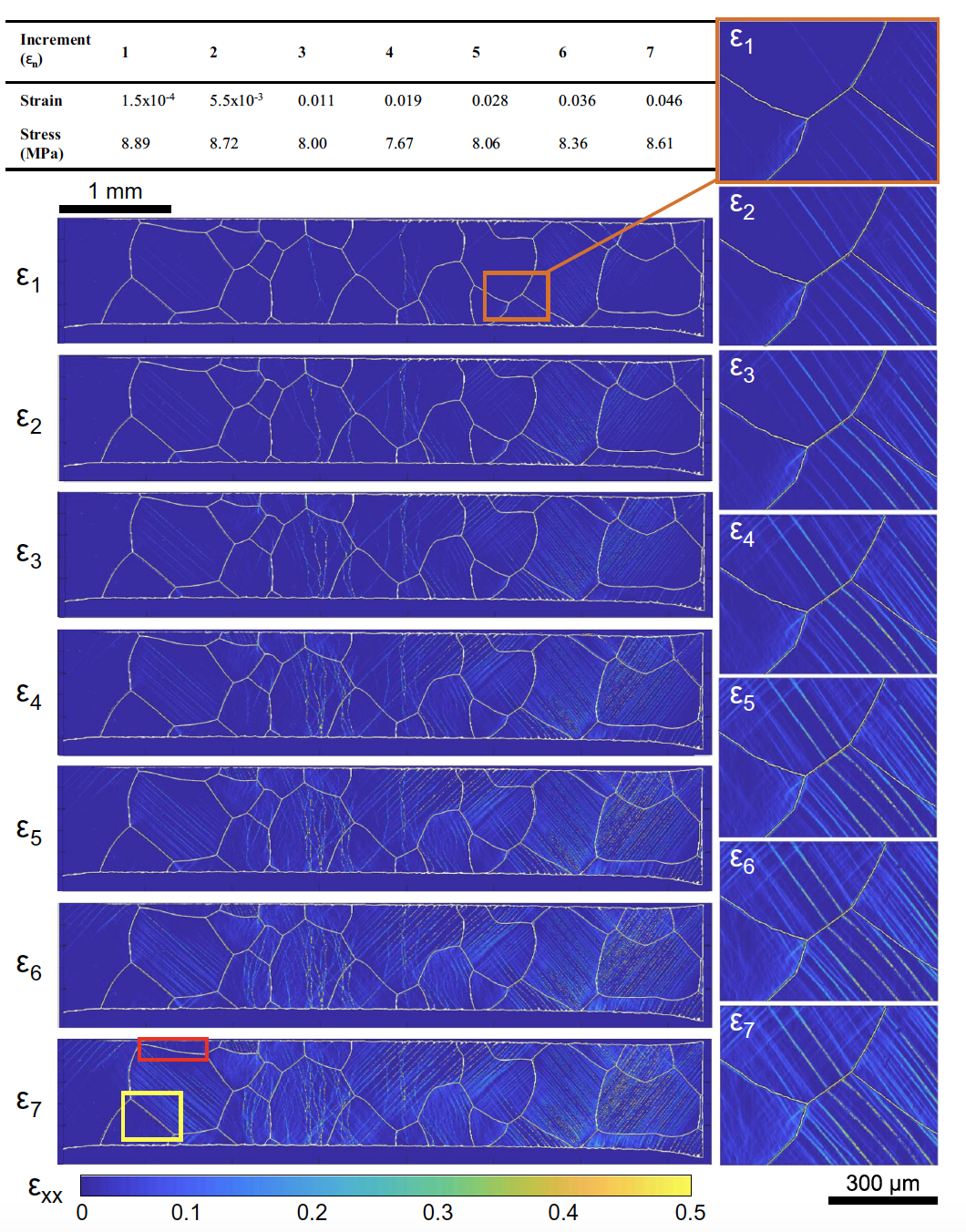

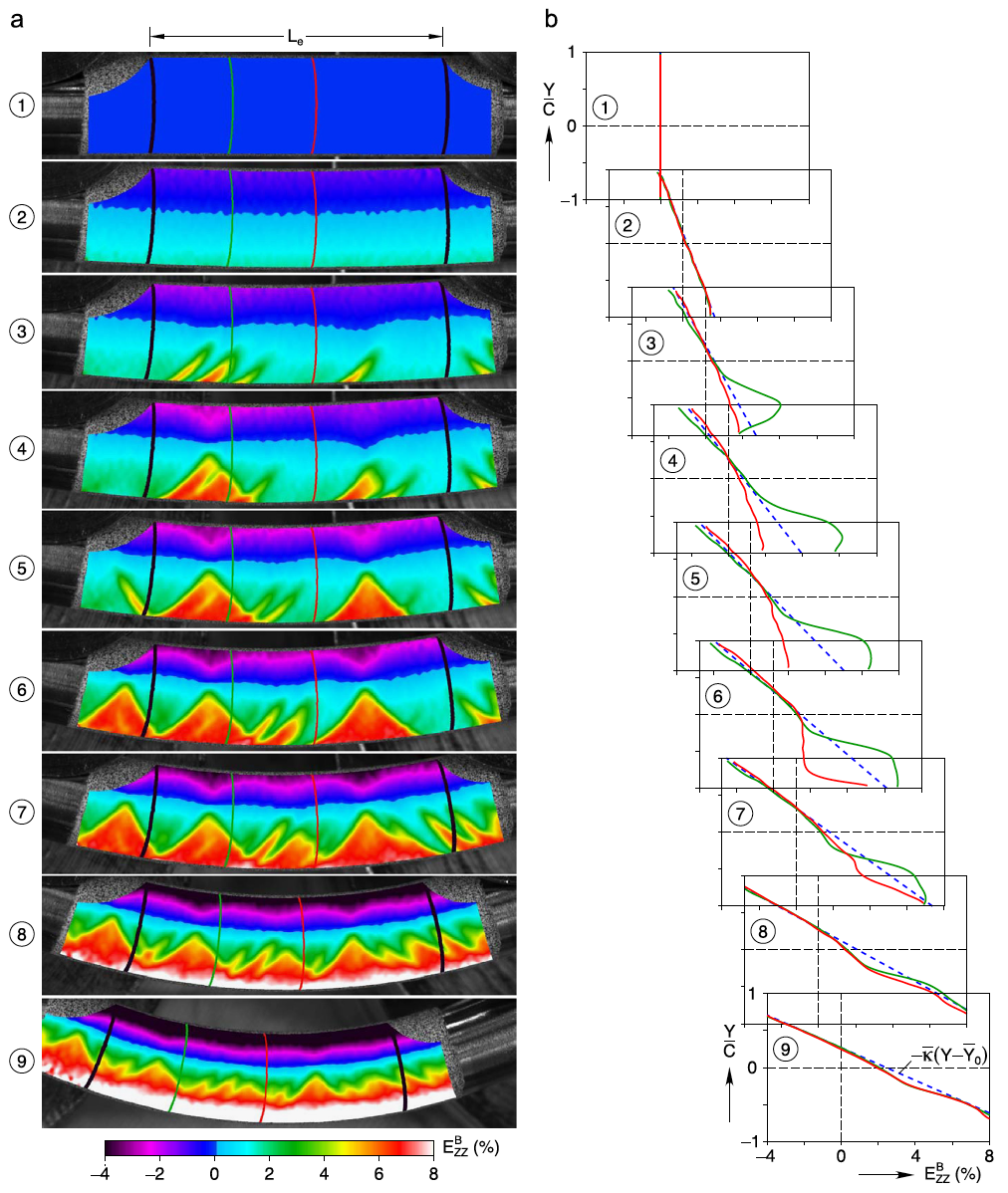

Dr. Samantha Daly

Finally, we shine a light on the work of Dr. Samantha (Sam) Daly in the Mechanical Engineering Department in the UCSB College of Engineering at the University of California at Santa Barbara. The Daly Lab uses digital image correlation with machine learning to examine structural materials, including metallic alloys and composites. As part of their research, the Daly group has developed new capabilities for mapping high spatial resolution deformations across mm-scale fields of view by using a combination of DIC and scanning electron microscopy. This allows them to explore the relationship between the microscale structure of a material and its mechanical behavior, and to capture critical deformation phenomena such as early damage, slip, and twinning across thousands of grains for high-throughput experiments. Their application of machine learning approaches to DIC data is enabling new insights into materials behavior and design.

Dr. Daly’s advice to those interested in an engineering career: “As an engineer, you’re going to try new things, and some of them are not going to work. Some of them will flat out fail. And that’s completely okay; it’s not only okay, but fully expected. Failures are central to the process of finding things out, and they usually teach us far more than our successes do. It’s the ability to pick yourself up, dust yourself off, and head into the fray again – knowing more now about what doesn’t work – that can lead you to creative and beautiful solutions. One of the things that is so great about being an engineer is the license to explore – to try new things, to fail, to overcome – and the thrill of figuring things out.”

https://labs.me.ucsb.edu/daly/samantha/

Fig 1: Machine-learning enabled twin identification across 1,500 grains from DIC data obtained in a scanning electron microscope. The 5.7 mm x 3.4 mm deformation map contains 100 million data points (Chen and Daly, Mat Sci Eng A, 736: 61-75, 2018).

Fig 2: Stitched SEM-DIC of high purity columnar aluminum enables new insights into the interactions between slip transmission and grain boundary sliding. 60 FOVs were correlated using Vic2D and stitched for a total of 43.5 million data points across the specimen gage. (Linne et al., Exp Mech 59: 643-658, 2019).

Fig 3: Axial DIC strain fields (left) and line profiles (right) of a Nitinol tube under bending. Nitinol is a unique material that is used extensively in biomedical applications because of its superelastic properties. DIC allows us to see the extent of deformation heterogeneity and that locally plane sections do not remain plane, informing the predictive modeling of these materials (Reedlunn et al., JMPS, 63: 506-547, 2014).